Trade Assurance 30 power saving induction steel melting furnace, electrical induction melting

Melting metals with induction heating provides reliable, repeatable, non-contact, safe and energy-efficient heat in the least amount of time.. Melting Point: Carbon Steel: 1425-1540°C (2597-2800°F) Stainless Steel: 1375 - 1530°C (2500-2785°F) Aluminum: 660°C (1220°F) Copper: 1084°C (1983°F) Brass: 930°C (1710°F) Source.

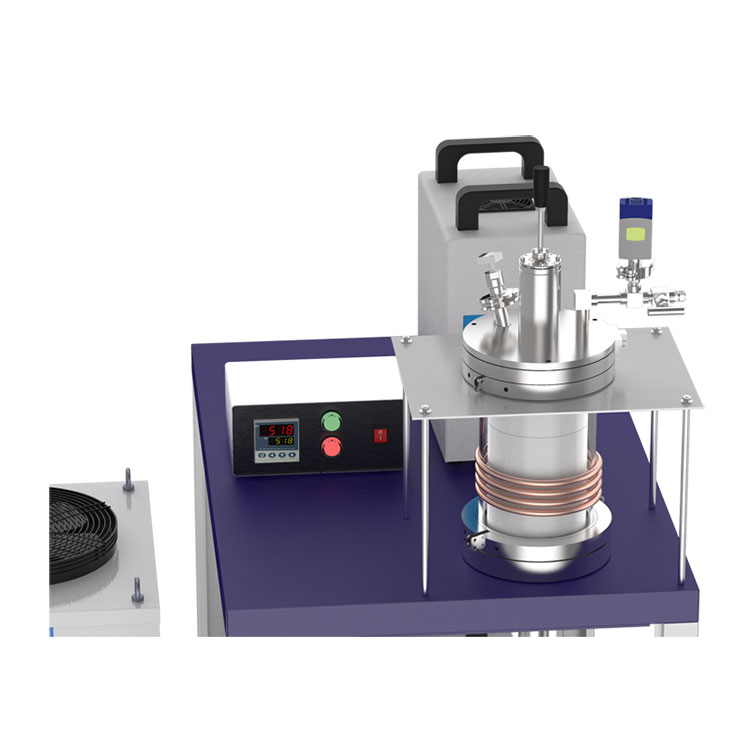

lab Vacuum induction melting furnace CYSP25VIM cyky

We design and manufacture the most advanced induction melting, heating, holding and pouring systems for virtually all metal and material processing. These include equipment for gray and ductile iron, steel, copper and copper-based alloys, aluminum, zinc, reactive metals, precious metals, silicon, and graphite heating, as well as numerous other.

China 200kg Steel Melting Electric Induction Furnaces Melting China Induction Furnace

Advanced Solutions for Automation in Steel Melting. Inductotherm scrap drying and automated charging systems enhance safety and keep pace with melting operations. High-capacity heavy steel shell coreless melting furnaces assure a steady supply of on-specification molten steel, while our Meltminder ® computer systems allow furnace operators to manage melting operations more precisely and.

25KW lab small temperaturecontrolled induction melting furnace Price

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

Induction Melting Stainless Steel HLQ INDUCTION EQUIPMENT CO.,LTD

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum, and precious metals.. The advantage of the induction furnace is a clean, energy-efficient and well-controlled melting process, compared to most other.

Induction Melting Furnaces Inductotherm Group

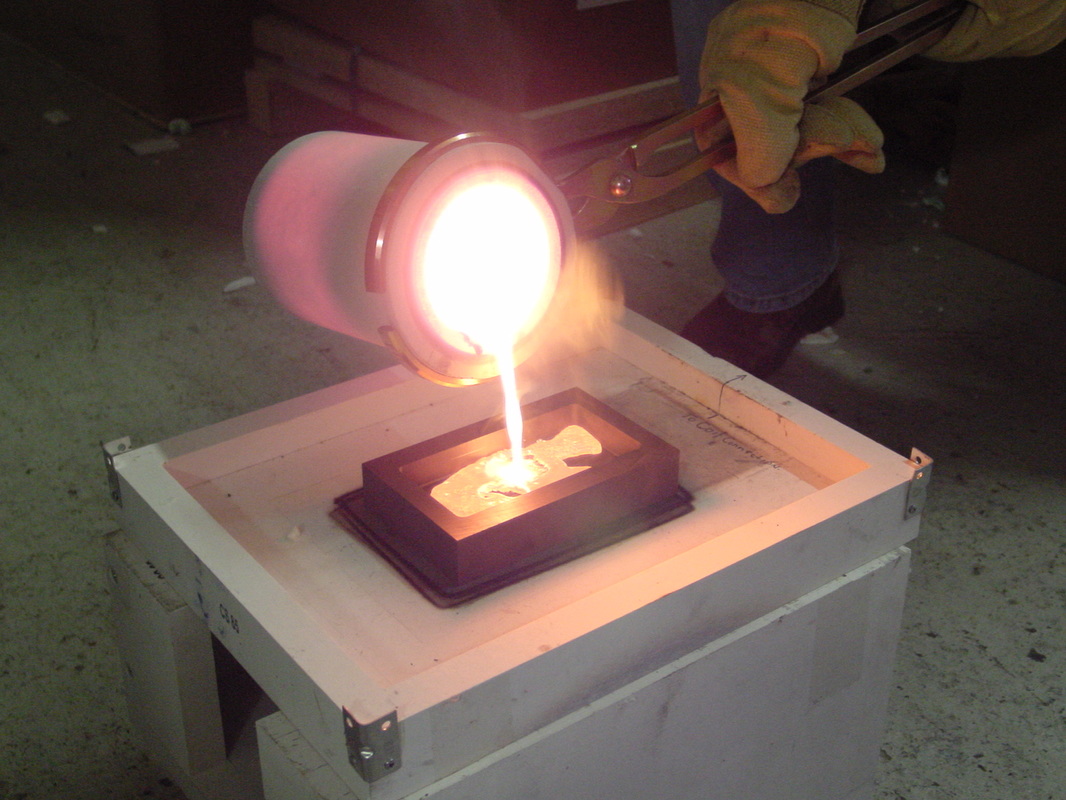

Induction Furnace Melting. Induction furnace melting is a process of melting metal by using electromagnetic induction to produce eddy current heating in metal materials in induction furnace, also called induction melting. It is applicable to melting high-grade alloy steel, high-grade cast iron, high-temperature alloy, electrical engineering.

110/220v 2kg gold, copper, silver aluminum iron steel induction melting furnace,jewelry melting

China. The percentage of electric steel produced with electric arc furnaces as the traditional melting unit around the world (without China, an exceptional case with 90 % oxygen steel) is around 45 %, and this percentage is growing. After the development of induction technology with inverter outputs of over 40 MW for crucible

Time to source smarter! Furnace, Building, Manufacturing

What is induction melting? Induction melting is a cost-effective and energy-efficient way to raise the temperature of a metal or ore to its melting point and to hold that temperature to perform metallurgical processes such as smelting, alloying, mixing, and casting.

Induction Melting Furnace Blog

In a conventional steel melting/refining process a carbon boil is employed with the intent of carbon reduction and hydrogen and nitrogen removal. Carbon boil is not a common practice in induction furnace melting, principally due to the fact that the stirring does not allow the development of a distinct slag layer on top of the melt.

Induction Furnace Metal Melting Furnace Smelt Gold Copper Iron Steel 1600℃/2912° eBay

Steel Shell Coreless Melting Furnace. ITC provides a wide range of steel shell coreless induction furnaces with matching power supplies. Ranging from 650 to 20 000 lbs (450 kg to 9 100 kg) in capacity, our heavy-duty steel shell design provides economic and performance benefits. By eliminating distortion, lining life is increased, and the.

induction melting steel powderUnited Induction Heating Machine Limited of China

The steel melting induction furnace system is utilized for melting and holding ferrous and non-ferrous metals including copper, aluminum, steel, iron, stainless steel, gold and more. It also has a melting capacity of 1 t/h to 25 t/h. Power range is from 250kw to 12000kw. More iron foundries take use of this type of induction furnace (such as.

steel induction furnace induction melting furnace realtime quotes, lastsale prices

It depends on the alloy and the selling price of the product. If a foundry is producing mainly carbon steel or low-alloy castings, the cost of higher-grade scrap may be significant. Temperature Control and Melting — Temperature control with induction melting is accurate and rapid. Applying indirect power for only a minute or two will increase.

induction melting steelUnited Induction Heating Machine Limited of China

Induction Melting Furnaces. Inductotherm's coreless induction furnaces offer superior performance and outstanding durability for all your melt shop needs regardless of the size of your foundry, melt shop or facility. We offer a variety of smaller induction furnaces to meet the demanding requirements of investment casters, specialty foundries.

Induction melting equipment for steel / iron / copper / aluminum / precious metals melting by

Induction melting had dramatic growth during the 1960s based on line frequency technology, and later with the large-scale introduction of medium frequency power supply during the 1980s. Making of mild steel in the induction furnace was first experimented during early 1980s and it gained popularity when the production of sponge iron utilizing.

Induction Furnace Metal Melting Furnace Smelt Gold Copper Iron Steel 1600℃/2912° eBay

The variation law of inclusions type and size in the vacuum induction melting process and ingot of Ni-based superalloy containing 70% return material was studied by industrial test sampling, and the mechanism of inclusions formation was analyzed with thermodynamic calculations. The results show that there are mainly two types of composite inclusions in the vacuum induction melting of Ni-based.

& Melting Power with Induction Generator Induction, Induction heating,

Inductotherm's Heavy Steel Shell Furnaces are ideal for melting all metals and silicon. Heavy Steel Shell Furnaces are also available with an optional wide-bodied design which have a significantly larger bath diameter and furnace opening and can be ideal depending on your application. They offer additional benefits such as lower installation.